Processing of structural analysis

The simplest method of getting a finite element solution is to use VisualFEA's

own processing capability. The finite element solver's capabilities are embedded

within VisualFEA. This makes VisualFEA much simpler to use than other finite

element p rograms which has separate module for processing, preprocessing and

postprocessing. In order to get into the processing stage for solution, choose

"Solve" item from  menu Then, "Analysis Options" dialog appears on the screen. The contents

of the dialog vary depending on the type of solution as will be described below.

Set the dialog items as desired and click

menu Then, "Analysis Options" dialog appears on the screen. The contents

of the dialog vary depending on the type of solution as will be described below.

Set the dialog items as desired and click  button.

Then, the processing starts, and goes on up to the completion of all the necessary

computation including assembling the system equations and solving them.

button.

Then, the processing starts, and goes on up to the completion of all the necessary

computation including assembling the system equations and solving them.

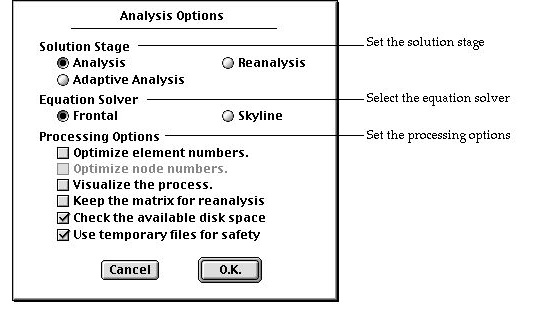

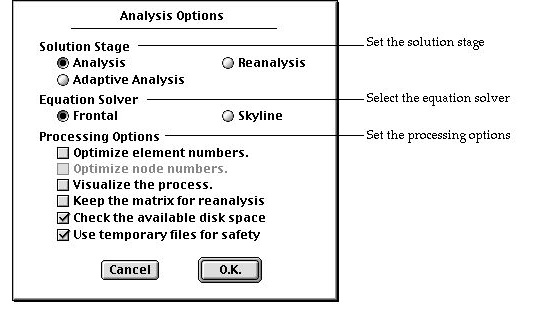

> Setting analysis options for linear static analysis

Choosing "Solve" item from  menu will pop up "Analysis Options" dialog as shown below, if you

have set the solution type as linear static.

menu will pop up "Analysis Options" dialog as shown below, if you

have set the solution type as linear static.

The solution type is initially set as linear static, and remains as it is,

unless you have checked any one of the check boxes under "Solution Type",

i.e., "Material nonlinear", "Geometric nonlinear" and "Dynamic."

The dialog has a few items setting the options related to the finite element

solution procedure.

| |

solution stage: The solution stage may be set as one of "Analysis",

"Reanalysis" and "Adaptive." If

you turn on "Adaptive" radio button, the solution procedure

turns into adaptive process. The analysis options for adaptive analysis

are described in the next section. So, only "Analysis" and "Reanalysis"

options are described in this section. The initial default setting of

the solution stage is "Analysis" which leads to the normal procedure

of processing based on assembling equations and solving them. Once the

system equations are assembled and solved, they may be used for subsequent

processing by setting the option as "Reanalysis" The reanalysis

option will eliminate most of the computing time for assembling and decomposing

the system equations. The reanalysis option is enabled and valid only

under the following conditions.

|

| |

|

- The system equations should have been solved in the previous session.

|

| |

|

- The files containing the system equations should exist in the same

directory (folder) as the data file.

|

| |

|

- Geometry, element properties, and boundary conditions should not have

been altered since the system equation files were created.

|

| |

|

- The analysis type is linear static, and not adaptive nor sequential.

|

| |

equation solver: You may choose one of two

methods of assembling and solving equations: frontal method and skyline

method. They are typical and the most widely used methods in finite element

analysis solvers. Skyline method uses only CPU memory, while frontal method

relies much on auxiliary memory such as a hard disk. Accordingly skyline

method demands much larger CPU memory space than frontal method. Skyline

method usually works faster than the frontal method which requires frequent

reading and writing with the auxiliary memory. The default setting is "Frontal."

If your computer is equipped with huge CPU memory, and you want faster solution,

choose "Skyline." Otherwise, you should keep the option as "Frontal."

In case you chose "Skyline," but the memory space is not sufficient,

the software will notify this by the following message box. If you click

button

of the dialog, the software will automatically switch the solver to "Frontal." button

of the dialog, the software will automatically switch the solver to "Frontal." |

| |

|

| |

processing options: You can turn on or off each of the processing

options by clicking the check box in front of each item. These settings

are applied during the processing stage. |

| |

|

- "Optimize element number" : This item is

enabled only when the equation solver is set as "Frontal" If

this option is turned on, optimization of element numbering is automatically

done prior to assembling the system equations.

|

| |

|

- "Optimize node number" : This item is enabled

only when the equation solver is set as "Skyline" If this option

is turned on, optimization of node numbering is automatically done prior

to assembling the system equations.

|

| |

|

- "Visualize the process" : If this option is turned on, a

graphical rendering of the model is provided along with the status of

the element stiffness matrix assembly.

|

| |

|

- "Keep the matrix for reanalysis" : The system equation files

are created at the start of matrix assemblage and removed

at the end of the processing. In order to keep these files for reanalysis,

this option should be turned on.

|

| |

|

- "Check the available disk space" : If this option is turned

on, the available disk space is checked while processing is going on.

If the disk space is not sufficient, the processing will pause with the

following notice so that you may secure enough space and resume the processing.

|

| |

|

|

| |

|

- "Use temporary file for safety" : If the

processing is abnormally interrupted due to system failure or any other

reasons, the data file may be spoiled or lost. In order to avoid such

risks, turn on this option. Then, a duplicate of the data file will be

created temporarily and used during the processing, and it will replace

the original file when the processing is successfully completed. The processing

procedure is initiated when you click  button

of the dialog, after setting all the appropriate items. button

of the dialog, after setting all the appropriate items.

|

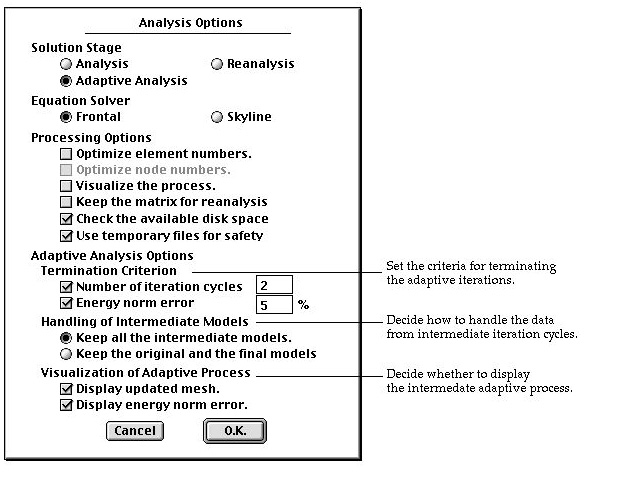

> Setting analysis options for adaptive analysis

If you click "Adaptive analysis" radio button of "Analysis Options"

dialog, the dialog expands with additional items as shown below. The upper part

of the dialog has the original items, and the bottom half includes new items

as follows:

| |

termination criterion: The adaptive iteration continues

until one of the conditions set for its termination is satisfied. These

conditions are termed here as the termination criterion. You may validate

or invalidate each one of the following termination criteria by checking

or unchecking the boxes in front of them. If the box is checked, the corresponding

criterion is applied.

|

| |

|

- number of iteration cycles: The number of iteration

cycles can be restricted by checking this item, and setting the number.

Iteration terminates when the number of cycles reaches the number.

|

| |

|

- energy norm error: Iteration terminates when maximum

energy norm error over the whole solution domain gets smaller than the

criterion set as the limiting energy norm error. If both of the termination

criteria are checked, iteration terminates when any one of them is fulfilled.

|

| |

|

|

| |

handling of intermediate models: It is

the option determining how to treat the model data created at the intermediate

stages of iterations.

|

| |

|

- "Keep all the intermediate models": If this radio button

is turned on, the modeling data and analysis results obtained during the

intermediate cycles of adaptive iteration are saved, and can be retrieved

for later use.

|

| |

|

- "Keep the original and the final models": If this radio button

is turned on, the intermediate modeling and analysis data are discarded,

and only the original and the final data are saved.

|

| |

visualization of adaptive process: It is the option related

with visualizing the model and/or energy norm error while the adaptive

iteration process is going on.

|

| |

|

- "Display updated mesh": If this radio button is turned on,

the meshes generated at each step of adaptive iterations are plotted.

|

| |

|

- "Display energy norm error": If this radio button is turned

on, the energ y norm error distribution is displayed by contour at each

step of adaptive iterations. (This option may not work for the current

version of VisualFEA.)

|

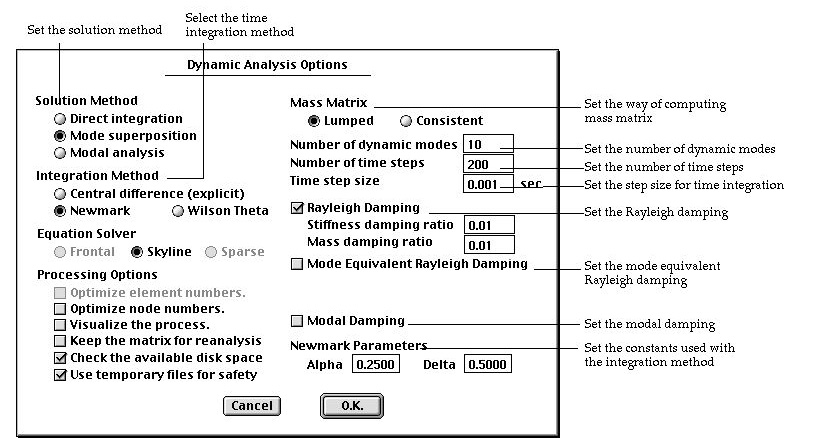

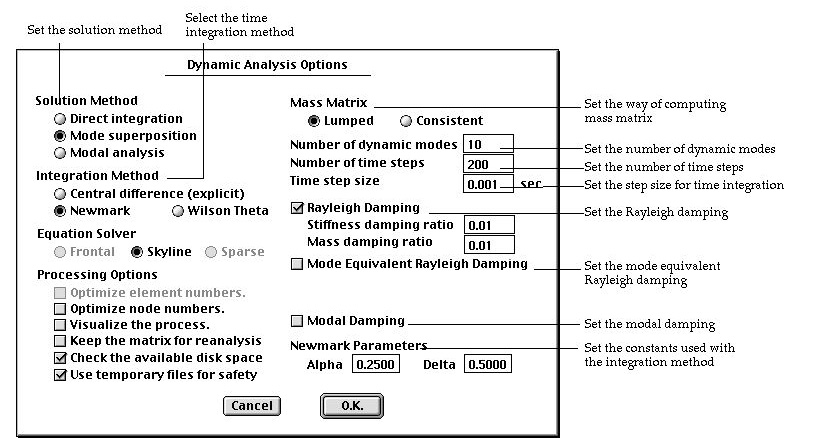

> Setting analysis options for dynamic analysis

Choosing "Solve" item from  menu

will popup "Dynamic Analysis Options" dialog as shown below, if you

have set the solution type as dynamic. The solution type

can be set by using the "Project Setup" dialog.

menu

will popup "Dynamic Analysis Options" dialog as shown below, if you

have set the solution type as dynamic. The solution type

can be set by using the "Project Setup" dialog.

| |

solution method : This option determines how to get

the dynamic analysis results. VisualFEA supports 3 methods of performing

dynamic analysis.

|

| |

|

- direct integration: No transformation is applied for integration in

time. The nodal displacements are obtained directly at each time step.ble

solution.

|

| |

|

- mode superposition: Time integration is operated on the participation

factors of dynamic modes. Thus, the dynamic modes are

extracted first through eigenvalue analysis, and the system equations

are formed in terms of participation factors of these dynamic modes. The

nodal displacements are obtained by superposing the dynamic modes at each

time step.

|

| |

|

- modal analysis: Only dynamic modes are extracted, No time integration

is performed. Other analysis results including nodal displacements are

not computed.

|

| |

integration method : This applies to the

integration in time for both the direct integration method and the mode

superposition method.

|

| |

|

- "Central difference (explicit)": A explicit

integration method, in which the stiffness matrix is not decomposed. The

mass matrix is decomposed only when consistent mass matrix is used. The

solution may diverge if the time step is larger than the critical value.

|

| |

|

- "Newmark": An implicit method with linear

acceleration controlled by parameters a and d, which can be set by the

user.

|

| |

|

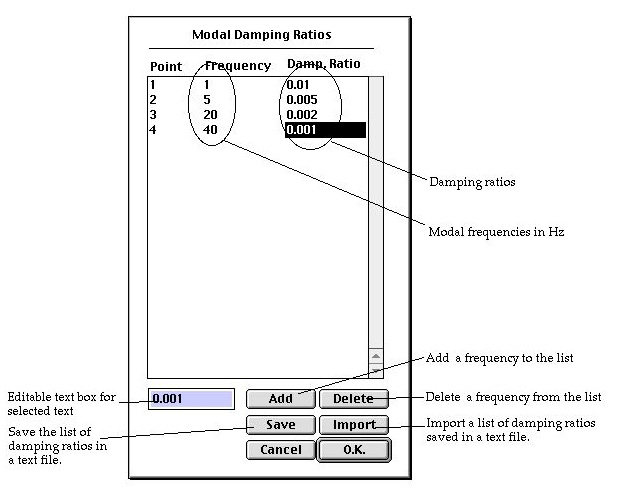

- "Wilson Theta": An implicit method with

linear acceleration controlled by an input parameter q, which can be set

by the user.

|

| |

mass matrix : There are following two options

in computing the element mass matrix.

|

| |

|

- "Lumped": The mass matrix is computed by assuming that element

mass is concentrated at nodal points.

|

| |

|

- "Consistent": The mass matrix is computed by interpolation

consistent with that used for the stiffness matrix.

|

| |

number of dynamic modes : To specify the number of dynamic

modes used for mode superposition. This item is valid only when the solution

method is set as mode superposition.

|

| |

number of time steps : The number of steps included for time

history analysis. The total duration of the analysis is determined by

the number of steps and the step size which is the next input item.

|

| |

time step size : The length of time from one step to the

next. Equal step size is assumed for the whole duration of the analysis.

|

| |

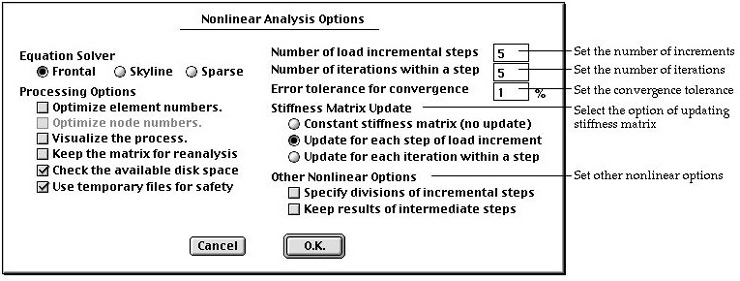

Rayleigh damping : If this item is checked,

Rayleigh damping is assumed,

|

| |

|

which is the form of  .

And the following 2 sub-items pop up. .

And the following 2 sub-items pop up.

|

| |

|

- "Stiffness damping ratio": This is the stiffness damping

coefficient b of the above equation.

|

| |

|

- "Mass damping ratio": This is the mass damping coefficient

a of the above equation.

|

| |

mode equivalent Rayleigh damping : If this item is checked,

Rayleigh damping is assumed, but is re p resented by 2 modal damping ratios

which appear as additional input items.

|

| |

|

- "Mode 1 damping ratio":

|

| |

|

- "Mode 2 damping ratio":

|

| |

|

|

| |

There is a following relationship between the Rayleigh

damping coefficients( and ) and the modal damping ratios (  and

and  ).

). |

| |

|

|

| |

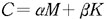

modal damping : One method of assigning damping characteristic

is to assume an individual damping ratio for each dynamic mode. It is

termed here as modal damping. However, information on dynamic modes is

not available prior to completing the modal analysis. Thus, the damping

ratio are specified as a function of modal frequency.

|

| |

If you click this item, there appears  button

which is used to launch "Modal Damping Ratio" dialog. A table

of modal frequencies and paired damping ratio can be specified using this

dialog. The damping ratio for a given frequency is estimated by interpolating

the values given in this table. button

which is used to launch "Modal Damping Ratio" dialog. A table

of modal frequencies and paired damping ratio can be specified using this

dialog. The damping ratio for a given frequency is estimated by interpolating

the values given in this table.

|

| |

|

| |

Acceleration parameters : parameter(s) for

linear acceleration of time integration. There are different parameters

depending on the method of time integration. The input items change as

the method of integration changes.

|

| |

|

- central difference method: no input parameters for

this method of integration.

|

| |

|

- Newmark: There are 2 parameters a and d. The default values, a=0.25

and d=0.5 are used for unconditionally stable solution.

|

| |

|

|

| |

|

- Wilson ¥è: There is a parameter q. The default value is q=1.4. The value

of should be 1.37 or greater for unconditionally stable solution.

|

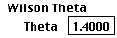

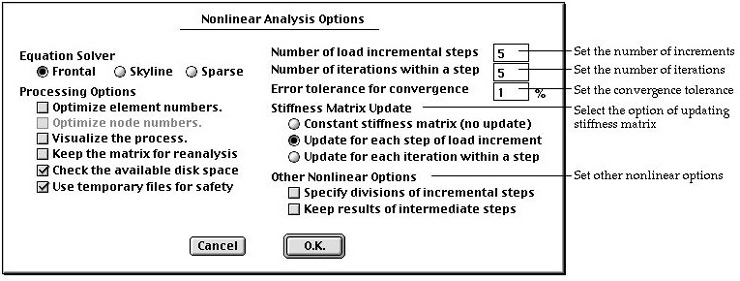

> Setting analysis options for nonlinear analysis

Choosing "Solve" item from  menu will pop up "Nonlinear Analysis Options" dialog as shown below,

if you have set the solution type as material nonlinear, or geometric

nonlinear. The solution type can be set by using the "Project Setup"

dialog.

menu will pop up "Nonlinear Analysis Options" dialog as shown below,

if you have set the solution type as material nonlinear, or geometric

nonlinear. The solution type can be set by using the "Project Setup"

dialog.

| |

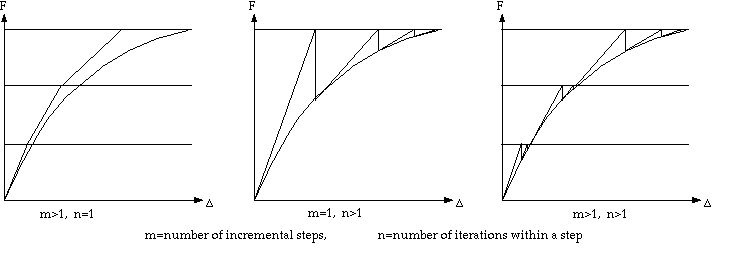

number of load incremental steps : It is the number

of steps for solution of a nonlinear problem by incremental

method. If this value is 1, a simple iterative solution is applied. Otherwise,

the total load is divided into as many segments as this number, and applied

incrementally through the nonlinear solution process.

|

| |

number of iterations within a step : The maximum limit in

the number of iterations within an incremental step for solution of nonlinear

equation. If this value is 1, simple incremental procedure is applied.

|

| |

error tolerance for convergence

: This convergence criterion applies to the iterative

procedure within an incremental step. The iteration is terminated if either

the percentage of the residual force falls below this level, or the number

of iterations reaches the maximum limit.

|

| |

< Number of load increments and number of iterations

>

|

| |

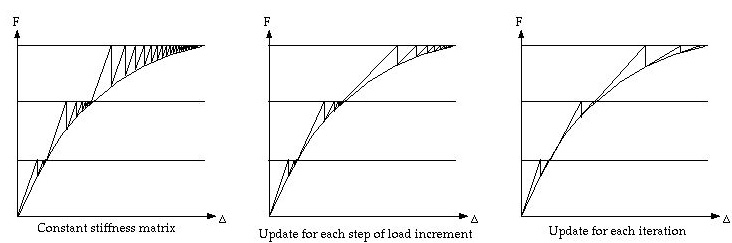

options for stiffness matrix update: There are following

3 options of updating stiffness matrix throughout the incremental and

iterative process.

|

| |

|

- "Constant stiffness matrix (no update)": If this button is

turned on, the stiffness matrix is not updated throughout the whole incremental

and iterative process. Thus, the stiffness matrix is computed only once

and no additional time is required for its update. However, this option

leads to large number of iterations as shown in the figure below.

|

| |

|

- "Update each step of load increment": If

this button is turned on, the stiffness matrix is updated only for the

first iteration of each load increment. The stiffness matrix remains constant

for all iterations within a load incremental step.

|

| |

|

- "Update each iteration within a step": If this button is

turned on, the stiffness matrix is updated for every iteration throughout

the whole process. This option takes more time for updating stiffness

matrix, but requires smaller number of iterations.

|

| |

|

< Schemes of stiffness matrix update >

|

| |

other nonlinear option:

|

| |

|

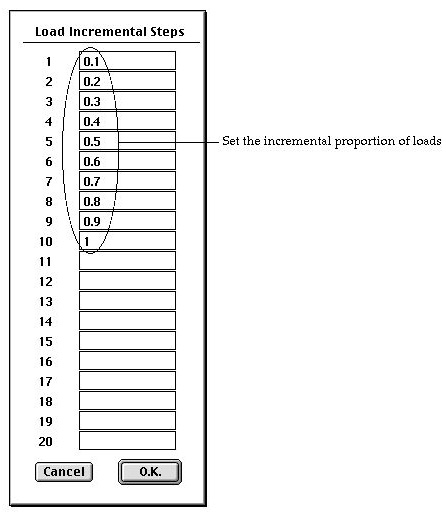

- "Specify division of incremental

steps" : This item is not checked by default, and the sizes of all

load increments are equal. If you check this item, the following "Load

Incremental Steps" dialog pops up. Initially the editable text boxes

are filled with uniformly divided incremental portions of the load. These

incremental proportions can be modified by editing the text. boxes |

| |

|

|

| |

|

- "Keep results of intermediate steps" : If this

item is checked, the solution data obtained at every incremental step is

saved, and can be retrieved for later use. |

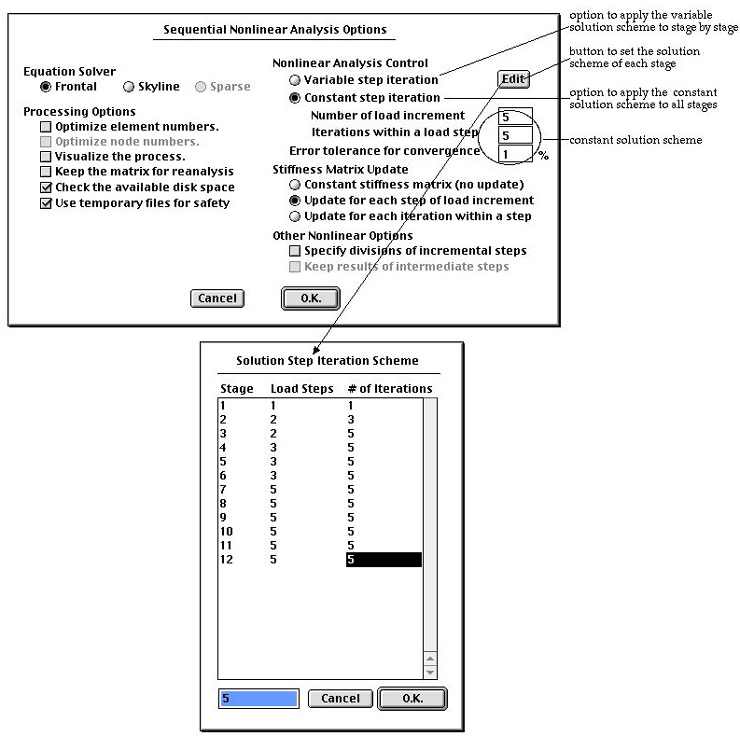

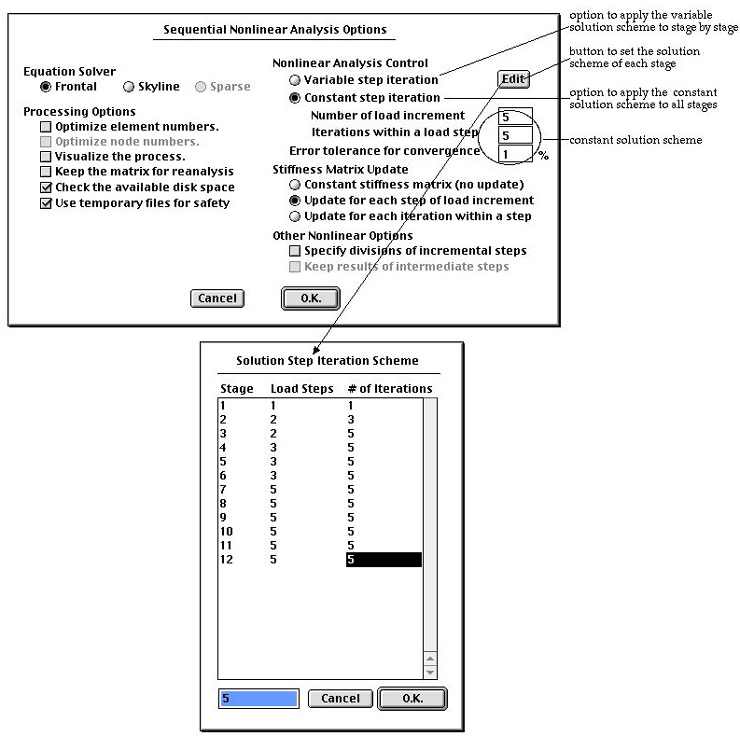

> Setting analysis options for sequentially staged modeling

As for linear analysis, the same dialog is used for both non-staged and staged

modeling. In the case of nonlinear analysis, dialog for sequentially staged

modeling has a few more items than the dialog for non-stage modeling. They are

related to incremental and iterative solution scheme for each stage. In order

to apply constant number of incremental steps and iterations, turn on "Constant

step iteration" radio button in the dialog and then insert the number of

incremental steps and iterations in the editable text box. In order to differentiate

the incremental and iterative scheme from stage to stage, turn on "Variable

step iteration" ratio button. And click  button.

Then, "Solution Step Iteration Scheme" dialog appears. You may set

the number of load steps and the number of iterations using this dialog. The

dialog displays as many rows as the number of stages. At the beginning , each

row is assigned with equal number of incremental steps and equal number of iterations.

Set new values by editing the existing ones, and click

button.

Then, "Solution Step Iteration Scheme" dialog appears. You may set

the number of load steps and the number of iterations using this dialog. The

dialog displays as many rows as the number of stages. At the beginning , each

row is assigned with equal number of incremental steps and equal number of iterations.

Set new values by editing the existing ones, and click  button

to complete the setting.

button

to complete the setting.

![]()

![]() menu Then, "Analysis Options" dialog appears on the screen. The contents

of the dialog vary depending on the type of solution as will be described below.

Set the dialog items as desired and click

menu Then, "Analysis Options" dialog appears on the screen. The contents

of the dialog vary depending on the type of solution as will be described below.

Set the dialog items as desired and click ![]() button.

Then, the processing starts, and goes on up to the completion of all the necessary

computation including assembling the system equations and solving them.

button.

Then, the processing starts, and goes on up to the completion of all the necessary

computation including assembling the system equations and solving them. ![]() menu will pop up "Analysis Options" dialog as shown below, if you

have set the solution type as linear static.

menu will pop up "Analysis Options" dialog as shown below, if you

have set the solution type as linear static.

![]() menu

will popup "Dynamic Analysis Options" dialog as shown below, if you

have set the solution type as dynamic. The solution type

can be set by using the "Project Setup" dialog.

menu

will popup "Dynamic Analysis Options" dialog as shown below, if you

have set the solution type as dynamic. The solution type

can be set by using the "Project Setup" dialog.

![]() menu will pop up "Nonlinear Analysis Options" dialog as shown below,

if you have set the solution type as material nonlinear, or geometric

nonlinear. The solution type can be set by using the "Project Setup"

dialog.

menu will pop up "Nonlinear Analysis Options" dialog as shown below,

if you have set the solution type as material nonlinear, or geometric

nonlinear. The solution type can be set by using the "Project Setup"

dialog.

![]() button.

Then, "Solution Step Iteration Scheme" dialog appears. You may set

the number of load steps and the number of iterations using this dialog. The

dialog displays as many rows as the number of stages. At the beginning , each

row is assigned with equal number of incremental steps and equal number of iterations.

Set new values by editing the existing ones, and click

button.

Then, "Solution Step Iteration Scheme" dialog appears. You may set

the number of load steps and the number of iterations using this dialog. The

dialog displays as many rows as the number of stages. At the beginning , each

row is assigned with equal number of incremental steps and equal number of iterations.

Set new values by editing the existing ones, and click ![]() button

to complete the setting.

button

to complete the setting.