Surface mesh generation by sweeping operations

VisualFEA supports the following 4 types of sweeping operations which may be

used for surface mesh generation:

| |

Extrusion |

| |

Translation |

| |

Revolution |

| |

Twisting |

Sweeping creates a surface mesh by traversing the seed curves along a path

defined in space. The sweeping operations, i.e., extrusion, translation, revolution,

and twisting are distinguished by the characteristics of their sweeping path.

The sweeping path for extrusion is a single straight line. Any continuous curve

passing through, or meeting at the seed curve, may be used as the path for translation.

The paths for revolution are circles with their centers along the axis

of revolution. Twisting uses helical path for mesh generation. The commands

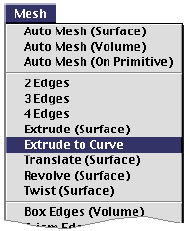

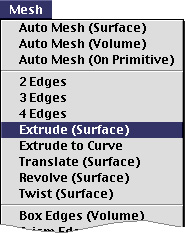

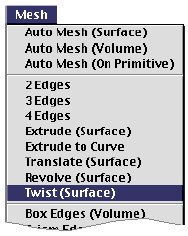

for surface mesh generation by sweeping are provided as menu items in  menu.

menu.

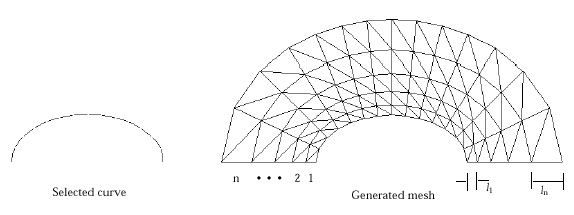

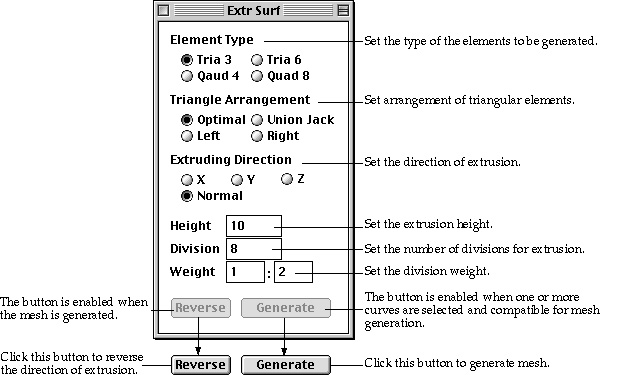

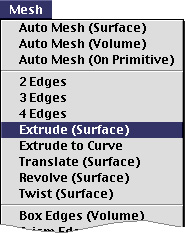

> Generating mesh by extrusion

|

A surface mesh can be generated by extruding

selected curves up to the specified height and in the specified direction.

The height of the extrusion is entered using the "Extr Surf" dialog. |

| |

1) Choose "Extrude(Surface)" from

menu. menu.

|

| |

The curve selection tool  is

automatically activated, and "ExtrSurf" dialog box appears. is

automatically activated, and "ExtrSurf" dialog box appears. |

| |

|

| |

2) Set the element type. |

| |

Choose one of the 4 element types given as radio buttons in

the dialog. |

| |

3) Select the type of arrangement for triangular elements.

|

| |

The triangular elements can be generated in the 4 different

types of arrangement as explained in the previous section "Generating

mesh using 2 edges" |

| |

4) Set the direction of extrusion. |

| |

The mesh may be extruded either in the direction of a coordinate

axis, or in the direction normal to the seed curve. The normal direction

is determined independently at each of the extruding nodes on the seed curve. |

| |

5) Enter the height of extrusion. |

| |

Extrusion height is the distance from the seed curve to the

extent of the mesh generation. |

| |

6) Enter the number of divisions for extrusion. |

| |

Specify how many rows of elements to be generated by extrusion. |

| |

7) Enter the weight of division density. |

| |

Enter the weight of division density in the form of w1:wn

, which is the ratio between width of elements at the starting part and

at the ending part of extrusion. |

| |

8) Select curves forming seed curves for extrusion. |

| |

All the selected curves should be divided, and form an edge,

which may be one curve or serially connected curves. The edge may be either

open or closed.  button

is enabled when an edge is formed properly for mesh generation. button

is enabled when an edge is formed properly for mesh generation. |

| |

9) Click  button. button.

|

| |

A surface mesh is generated by extruding the seed curve, if

the selected curves are compatible for mesh generation. Otherwise, the action

is ignored after a message "Incompatible curve selection for extrusion."

|

At this stage, even if the cycle ended with failure,  button

is disabled as it should be at step 2).

button

is disabled as it should be at step 2).  button

is enabled, only when mesh generation is successful. In case the mesh is generated

opposite to the desired direction, click

button

is enabled, only when mesh generation is successful. In case the mesh is generated

opposite to the desired direction, click  button

to revert the direction of extrusion. Then, mesh will be regenerated with the

reverse direction. You may repeat the above procedure of generating mesh by

extrusion without issuing the command again, while "Extr Surf" dialog

remains on the screen. This mesh generation command is terminated by closing

the dialog box or issuing any other command.

button

to revert the direction of extrusion. Then, mesh will be regenerated with the

reverse direction. You may repeat the above procedure of generating mesh by

extrusion without issuing the command again, while "Extr Surf" dialog

remains on the screen. This mesh generation command is terminated by closing

the dialog box or issuing any other command.

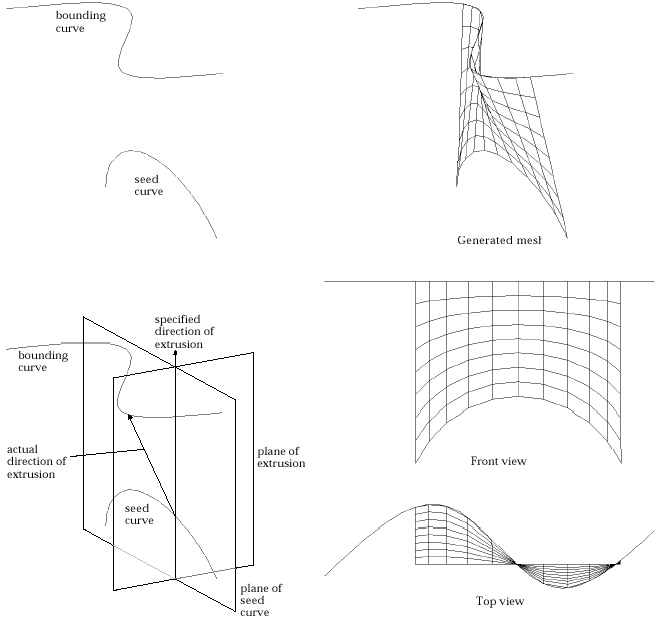

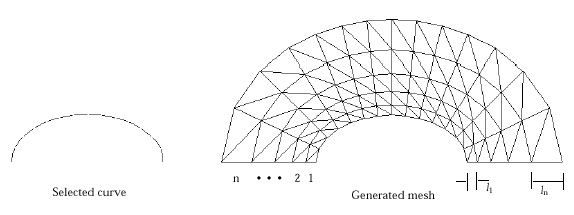

< A surface mesh generated by extrusion in normal direction

>

The direction of extrusion is not necessarily in the same plane as the seed

curve. Extrusion can be used effectively in creating 3-dimensional surface mesh

by extruding the seed curve out of its plane as shown in the example below.

< A 3-D surface mesh generated by extrusion in an out-of-plane

direction >

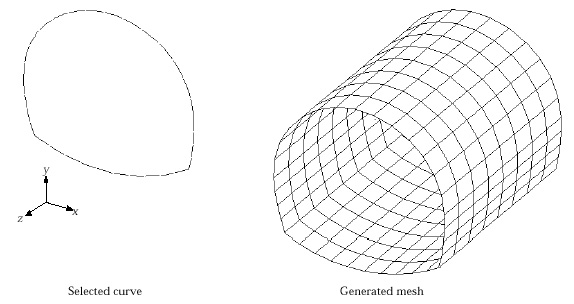

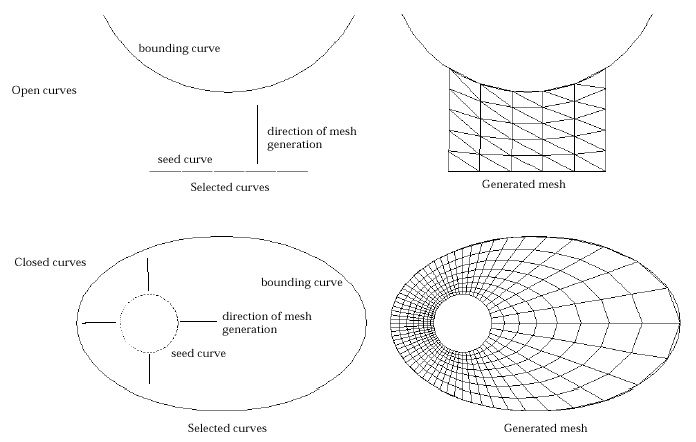

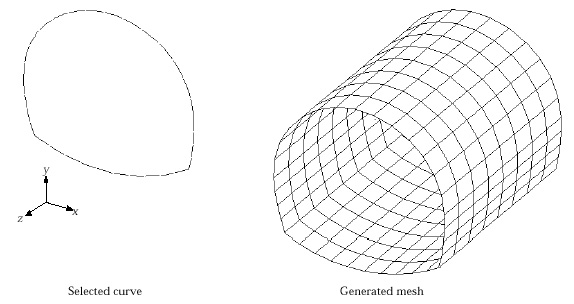

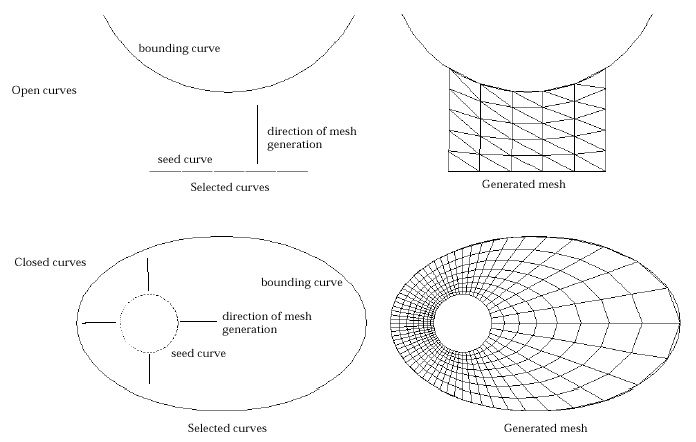

> Generating mesh by extrusion up to bounding curves

|

Instead of specifying the height of extrusion,

you may define the bound of the extrusion by selected curves. These curves

are termed here as "bounding curve." This method of mesh generation

is the same as the above described extrusion method except that the extent

of extrusion is determined not by its height but by the bounding curves.

The advantage of this method is that the direction of extrusion as well

as the boundary of the mesh can be controlled. |

| |

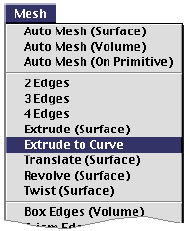

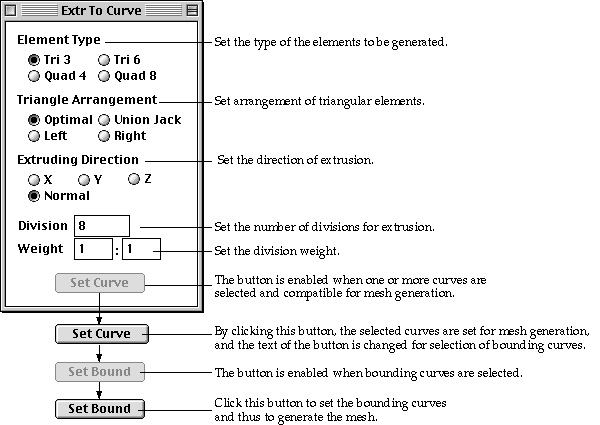

1) Choose "Extrude to Curve" from

menu. menu.

|

| |

The curve selection tool  is

automatically activated, and "Extr to Curve" dialog box appears. is

automatically activated, and "Extr to Curve" dialog box appears. |

| |

|

| |

2) Set the element type. |

| |

Choose one of the 4 element types given as radio buttons in

the dialog. |

| |

3) Select the type of arrangement for triangular elements.

|

| |

The triangular elements can be generated in the 4 diff e rent

types of arrangement as explained in the previous section "Generating

mesh using 2 edges". |

| |

4) Set the direction of extrusion. |

| |

The mesh may be extruded either in the direction of a coordinate

axis, or in the direction normal to the seed curve. The direction is always

signed toward the bounding curves. |

| |

If both the seed curves and the bounding curves are closed,

normal direction is the only option that can generate valid mesh by extrusion. |

| |

5) Set the number of divisions for extrusion. |

| |

Specify how many rows of elements are to be generated by extrusion. |

| |

6) Set the weight of division density. |

| |

Enter the weight of division density in the form of w1:wn

, which is the ratio between width of elements at the starting part and

at the ending part of extrusion. |

| |

7) Select curves forming seed curves for extrusion. |

| |

All the selected curves should be divided, and form an edge,

which may be one curve or serially connected curves.  button

is enabled when an edge is formed properly for mesh generation. button

is enabled when an edge is formed properly for mesh generation. |

| |

8) Click  button. button.

|

| |

The selected curves are reserved as the seed curves for mesh

generation, and the button changes into  indicating

that selection of bounding curves is expected in the next step. indicating

that selection of bounding curves is expected in the next step. |

| |

9) Select the bounding curves. |

| |

The selected bounding curves are highlighted in bright red

color. The dimmed  button

is enabled when bounding curves are selected. button

is enabled when bounding curves are selected. |

| |

10) Click  button. button.

|

| |

A mesh is generated by extruding the seed curves up to the

bounding curves.  button

is restored to button

is restored to  button.

It is now ready for generating another surface mesh. button.

It is now ready for generating another surface mesh. |

| |

The bounding curve should be closed if the seed curve is

closed, and should be open otherwise. If the bounding curves are open, they

must be long enough to cover the whole range of extrusion. Otherwise, the

mesh generation will be aborted with a message, ¡°Insufficient coverage of

the bounding curve.¡± |

<Mesh generated by extrusion up to bounding curves>

You may repeat the above procedure of mesh generation without issuing the command

again, while "Extr to Curve" dialog remains on the screen. This mesh

generation command is terminated by closing the dialog box or issuing any other

command.

< Determination of extruding direction in case the seed curve

and the bounding curve are not on the same plane >

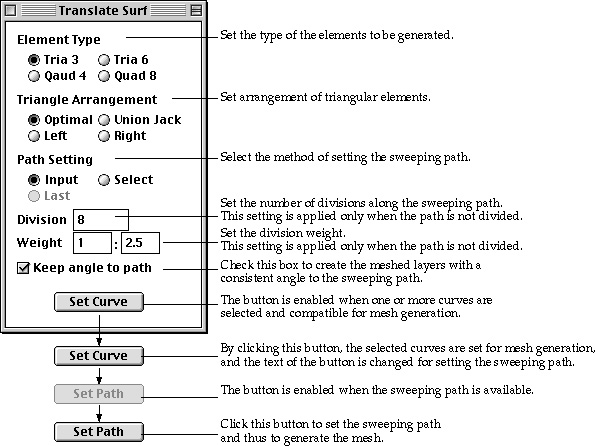

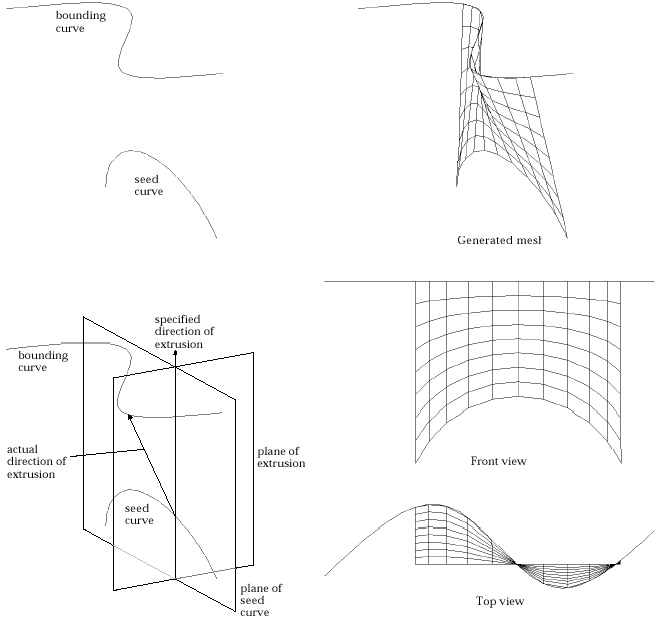

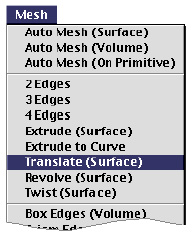

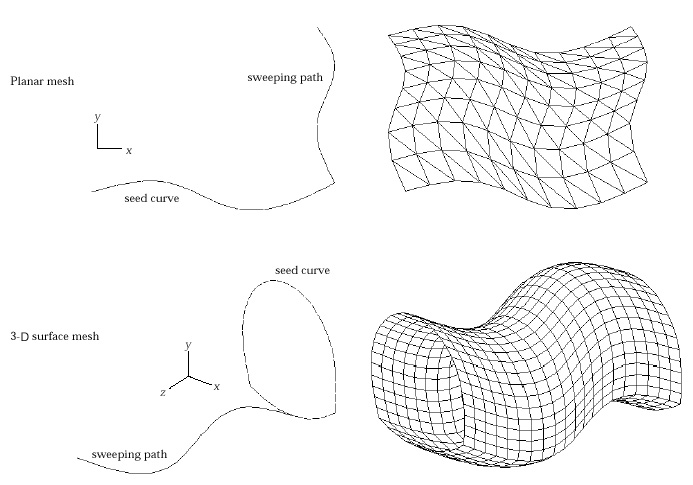

> Generating mesh by translation

|

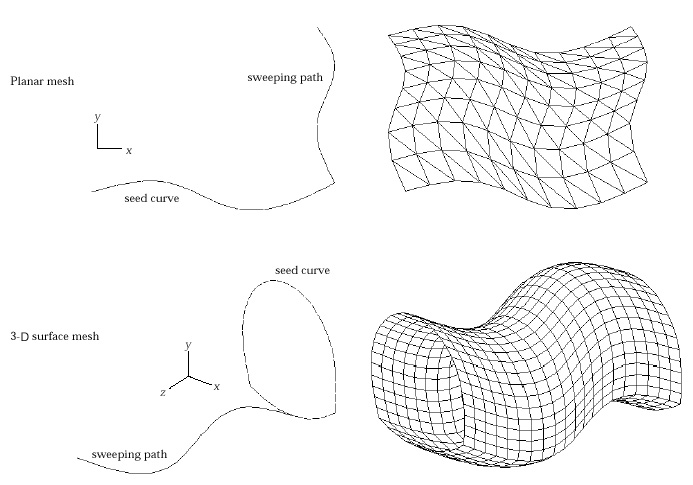

A surface mesh can be generated by translating

the selected seed curves along the specified sweeping

path. The boundaries of the generated elements are defined by a set of curves

parallel to the seed curves and the other set parallel to the sweeping path.

The previously described method of mesh generation by extrusion may be regarded

as a special case of this operation in which the sweeping path is a straight

line drawn in the specified direction. |

| |

1) Choose "Translate(Surface)" from  menu. menu.

|

| |

The curve selection tool  is

automatically activated, and "Translate Surf " dialog box appears. is

automatically activated, and "Translate Surf " dialog box appears. |

| |

|

| |

2) Set the element type. |

| |

Choose one of the 4 element types given as radio buttons in

the dialog. |

| |

3) Select the type of arrangement for triangular elements.

|

| |

Triangular elements can be generated in the 4 different types

of arrangement as explained in the previous section "Generating mesh

using 2 edges". |

| |

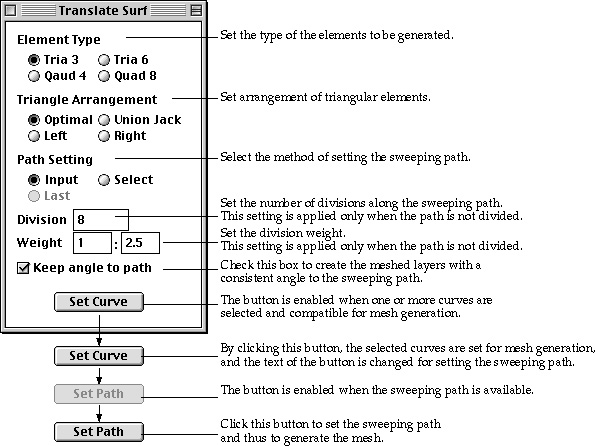

4) Select the option for path setting. |

| |

Choose one of the 3 options setting the sweeping path, "Input",

"Select" and "Last" by clicking the corresponding radio

button. The "Last" button is enabled only when this method of

mesh generation was applied at least once since the dialog box appeared. |

| |

5) Set the number of divisions for translation. |

| |

Specify how many rows of elements are to be generated by translation.

This setting is applied only when the sweeping path is not divided. If divided

curves are selected as the sweeping path, their divisions will be applied

regardless of this setting. |

| |

6) Check or uncheck "Keep angle to path" check box.

|

| |

If this check box is checked, the meshed layers are created

so that they have a constant angle with the sweeping path. Otherwise, all

the layers are made parallel. |

| |

7) Set the weight of division density. |

| |

Enter the weight of division density in the form of w1:wn

, which is the ratio between width of elements at the starting part and

at the ending part of translation. This setting is also applied only when

the sweeping path is not divided. |

| |

8) Select curves forming seed curves for translation. |

| |

All the selected curves should be divided, and form an edge,

which may be one curve or serially connected curves. The seed curves may

be open or closed.  button

is enabled when an edge is formed properly for mesh generation. button

is enabled when an edge is formed properly for mesh generation. |

| |

9) Click  button. button.

|

| |

The selected curves are reserved as the seed curves for mesh

generation, and the button changes into  indicating

that setting the sweepin path is expected in the next step. indicating

that setting the sweepin path is expected in the next step. |

| |

10) Set the sweeping path. |

| |

Set the sweeping path by the method selected at step 4). |

| |

|

"Input " : If the method is set as "Input"

one of the curve input tool is activated, and the cursor changes into shape.

And, it is now ready for creating a sweeping path by inputting a new curve.

At this step, line tool button is activated so that straight lines may be

entered. Any type of curves may be used as the sweeping path. In order to

input desired types of curves, click the corresponding curve tool button. |

| |

|

"Select" : If the method is set as "Select"

the curve selection tool is activated, and thus cursor changes into shape.

Select a curve which will be used as the sweeping path. Either divided or

undivided curves are acceptable. |

| |

|

"Last" : The sweeping path for last mesh generation

is applied again. So, it is not necessary to input or select the sweeping

path. This option can be used only when this method of mesh generation was

applied at least once since the dialog box appeared. |

| |

|

The sweeping path should be open, and its one end point

should meet with a node on the seed curve. The sweeping path may be one

curve or serially connected curves. If the sweeping path consists of more

than one curve, they must be either all divided or all undivided. Mixed

use of divided and undivided curves for sweeping path is not allowed. |

| |

11) Click button. |

| |

A mesh is generated by translating the seed curves along the

sweeping path. button is restored to button. It is now ready for generating

another surface mesh. The curve selection tool i s automatically activated,

if it is not in action. |

You may repeat the above procedure of mesh generation without

issuing the command again, while "Translate Surf" dialog remains on

the screen. This mesh generation command is terminated by closing the dialog

box or issuing any other command.

< Example of mesh generation by translation on plane and

in 3-D space>

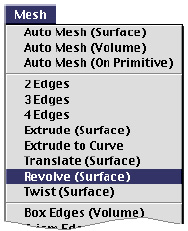

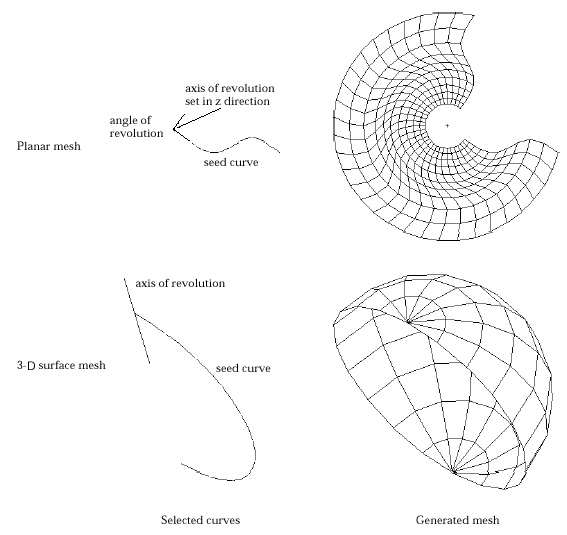

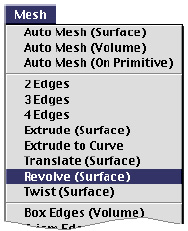

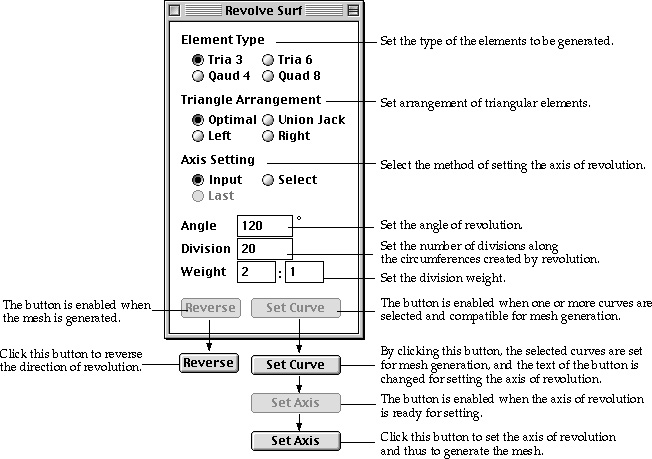

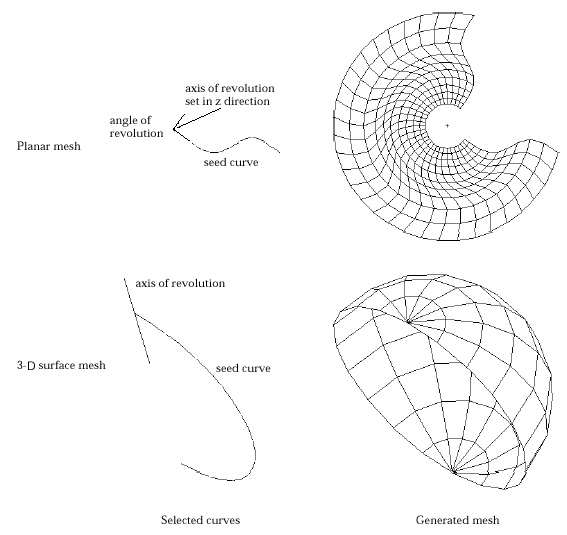

> Generating mesh by revolution

|

Curved surface elements are generated on the

surface of revolution created by revolving seed curves about the specified

axis. The latitude and the longitude of the surface form the boundaries

of the generated elements. The axis of revolution may be set interactively

in any desired direction. Either a partial or a full surface of revolution

is created depending on the specified angle. The direction of revolution

can be reversed if necessary. |

| |

1) Choose "Revolve (Surface)"

from  menu. menu.

|

| |

The curve selection tool  is

automatically activated, and "Revolve Surf " dialog box appears. is

automatically activated, and "Revolve Surf " dialog box appears. |

| |

|

| |

2) Set the element type. |

| |

Choose one of the 4 element types given as radio buttons

in the dialog. |

| |

3) Select the type of arrangement for triangular elements.

|

| |

The triangular elements can be generated in the 4 diff e

rent types of arrangement as explained in the previous section "Generating

mesh using 2 edges" |

| |

4) Select the option for setting the axis of revolution.

|

| |

Choose one of the 3 options setting the axis of revolution,

"Input", "Select" and "Last" by clicking the

corresponding radio button. The "Last" button is enabled only

when this method of mesh generation was applied at least once since the

program started. |

| |

5) Set the angle of revolution. |

| |

Insert the angle of revolution in the dialog box. The angle

should be greater than or equal to -360 and less than equal to 360

. Both -360 and 360 makes full surface of revolution. The negative

sign reverses the direction of revolution. |

| |

6) Set the number of divisions for revolution. |

| |

Specify how many rows of elements are to be generated by

revolution in circumferential direction. |

| |

7) Set the weight of division density. |

| |

Enter the weight of division density in the form of w1:wn

, which is the ratio between width of elements at the starting part and

at the ending part of revolution. |

| |

8) Select curves forming seed curves for revolution. |

| |

All the selected curves should be divided, and form an edge,

which may be one curve or serially connected curves. The seed curves may

be open or closed.  button

is enabled when an edge is formed properly for mesh generation. button

is enabled when an edge is formed properly for mesh generation. |

| |

9) Click  button. button.

|

| |

The selected curves are reserved as the seed curves for mesh

generation, and the button changes into  indicating

that setting the axis of revolution is expected in the next step. indicating

that setting the axis of revolution is expected in the next step. |

| |

10) Set the axis of revolution. |

| |

Set the axis of revolution by the method selected at step

4). |

| |

|

"Input" : If the method is set as "Input"

the line tool button is automatically activated, and the cursor changes

into shape. Input the axis of revolution following the same procedure as

that of creating a straight line. |

| |

|

"Select" : If the method is set as

"Select" the curve selection tool is activated, and thus cursor

changes into shape. Select a straight line which will be used as the axis

of revolution. |

| |

|

"Last" : The axis of revolution for

last mesh generation is applied again. So, it is not necessary to input

or select the axis. This option can be used only when this method of mesh

generation was applied at least once since the program started. |

| |

|

The sweeping path should be open, and its one end point

should meet with a node on the seed curve. The sweeping path may be one

curve or serially connected curves. If the sweeping path consists of more

than one curve, they must be either all divided or all undivided. Mixed

use of divided and undivided curves for sweeping path is not allowed. |

| |

11) Click  button. button.

|

| |

A mesh is generated by revolving the seed curves about the

axis of revolution.  button

is restored to button

is restored to  button.

The program is now ready for generating another surface mesh. The curve

selection tool button.

The program is now ready for generating another surface mesh. The curve

selection tool  is

automatically activated, if it is not in action. is

automatically activated, if it is not in action.  button

is enabled, only when mesh generation is successful. Clicking button

is enabled, only when mesh generation is successful. Clicking  button

reverses the sign of the revolution angle and regenerates the mesh. button

reverses the sign of the revolution angle and regenerates the mesh. |

You may repeat the above procedure of mesh generation without issuing the command

again, while "Revolve Surf" dialog remains on the screen. This mesh

generation command is terminated by closing the dialog box or issuing any other

command.

< Example of mesh generation by revolution in a plane and

in 3-D space>

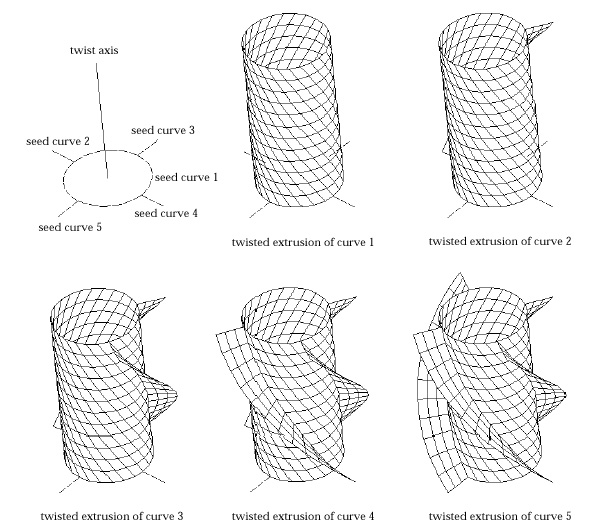

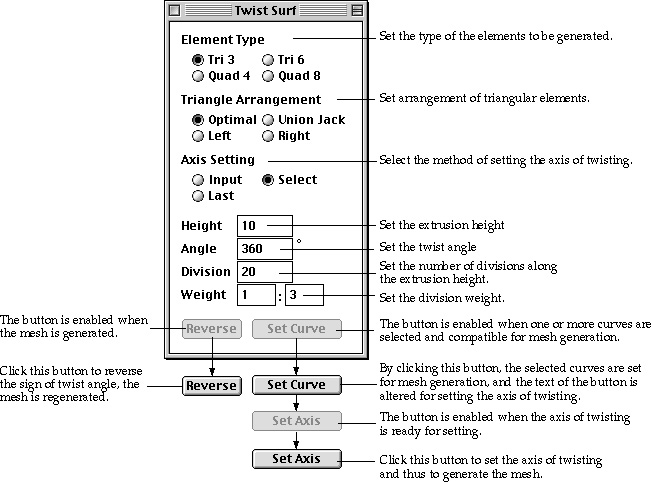

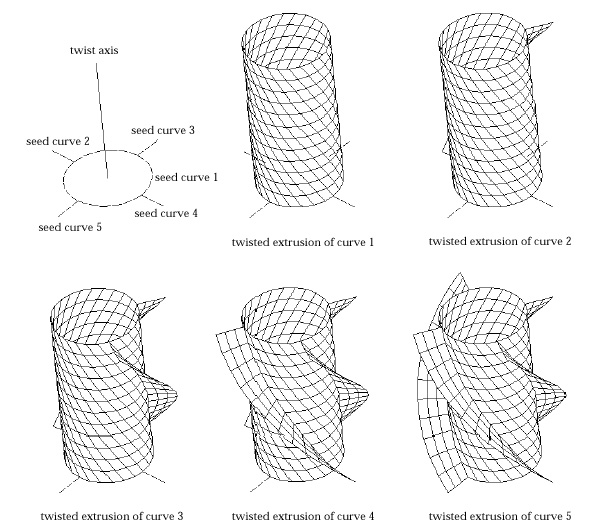

> Generating mesh by twisting

|

Twisting is a method of mesh generation by extrusion

combined with revolution. So, it may be termed as "Twisted

extrusion." Elements are generated on the surface which is formed by

extruding the selected seed curves along the specified axis while twisting

the direction of extrusion about the axis by the specified angle. Along

this twisted extrusion, the trace of a node on the seed curve makes a helix

on which new nodes are created. If the twist angle is set to zero, the resulting

mesh generation is identical to that of extrusion in the direction of the

twist axis. Likewise, if the extrusion height is set to zero, a surface

mesh of revolution is obtained. This method of mesh generation is useful

in modeling curved surfaces of spiral shape. |

| |

1) Choose "Twist (Surface)" from  menu. menu.

|

| |

The curve selection tool  is

automatically activated, and "Twist Surf" dialog box appears. is

automatically activated, and "Twist Surf" dialog box appears. |

| |

|

| |

2) Set the element type. |

| |

Choose one of the 4 element types given as radio buttons

in the dialog. |

| |

3) Select the type of arrangement for triangular elements. |

| |

Triangular elements can be generated in the 4 different types

of arrangement as explained in the previous section "Generating mesh

using 2 edges" |

| |

4) Select the option for setting the twist

axis. |

| |

Choose one of the 3 options setting the twist axis, "Input",

"Select" and "Last" by clicking the corresponding radio

button. The "Last" button is enabled only when this method of

mesh generation was applied at least once since the program started. |

| |

5) Set the extrusion height. |

| |

Insert the extrusion height in the dialog box. The direction

of extrusion is given by that of the twist axis which is directed from the

first input point to the second. |

| |

6) Set the twist angle. |

| |

Insert the twist angle in the dialog box. There is no limit

in the acceptable range of twist angle. The negative sign reverses the direction

of twist. |

| |

7) Set the number of divisions. |

| |

Specify how many rows of elements are to be generated in

the direction of the twisted extrusion. |

| |

8) Set the weight of division density. |

| |

Enter the weight of division density in the form of w1:wn

, which is the ratio between width of elements at the starting part and

at the ending part of twisting. |

| |

9) Select curves forming seed curves for twisting. |

| |

All the selected curves should be divided, and form an edge,

which may be one curve or serially connected curves. The seed curves may

be open or closed.  button

is enabled when an edge is formed properly for mesh generation. button

is enabled when an edge is formed properly for mesh generation. |

| |

10) Click  button. button.

|

| |

The selected curves are reserved as the seed curves for mesh

generation, and the button changes into  indicating

that setting the twist axis is expected in the next step. indicating

that setting the twist axis is expected in the next step. |

| |

11) Set the twist axis. |

| |

Set the twist axis by the method selected at step 4). |

| |

|

"Input" : If the method is set as "Input"

the line tool button is automatically activated, and the cursor changes

into shape. Input the twist axis following the same procedure as that of

creating a straight line. |

| |

|

"Select" : If the method is set as

"Select" the curve selection tool is activated, and thus cursor

changes into shape. Select a straight line which will be used as the twist

axis. |

| |

|

"Last" : The twist axis for last mesh

generation is applied again. So, it is not necessary to input or select

the axis. This option can be used only when this method of mesh generation

was applied at least once since the program started. |

| |

12) Click  button. button.

|

| |

A mesh is generated by twisted extrusion of the seed curve.

button

is restored to button

is restored to  button.

The program is now ready for generating another surface mesh. The curve

selection tool is automatically activated, if it is not yet activated. button.

The program is now ready for generating another surface mesh. The curve

selection tool is automatically activated, if it is not yet activated.  button

is enabled, only when mesh generation is successful. Clicking button

is enabled, only when mesh generation is successful. Clicking  button

reverts sign of the twist angle and regenerates the mesh. button

reverts sign of the twist angle and regenerates the mesh. |

You may repeat the above procedure of mesh generation without issuing the command

again, while "Twist Surf" dialog remains on the screen. This mesh

generation command is terminated by closing the dialog box or issuing any other

command.

< Example of modeling 3-D surfaces by twisting>

![]()

![]() menu.

menu.

![]() button

is disabled as it should be at step 2).

button

is disabled as it should be at step 2). ![]() button

is enabled, only when mesh generation is successful. In case the mesh is generated

opposite to the desired direction, click

button

is enabled, only when mesh generation is successful. In case the mesh is generated

opposite to the desired direction, click ![]() button

to revert the direction of extrusion. Then, mesh will be regenerated with the

reverse direction. You may repeat the above procedure of generating mesh by

extrusion without issuing the command again, while "Extr Surf" dialog

remains on the screen. This mesh generation command is terminated by closing

the dialog box or issuing any other command.

button

to revert the direction of extrusion. Then, mesh will be regenerated with the

reverse direction. You may repeat the above procedure of generating mesh by

extrusion without issuing the command again, while "Extr Surf" dialog

remains on the screen. This mesh generation command is terminated by closing

the dialog box or issuing any other command.